The Global Flow of Energy: Understanding LNG Transport and Trade

Liquefied Natural Gas (LNG) has emerged as a crucial component of the global energy mix, enabling natural gas—the cleanest-burning fossil fuel—to be transported across oceans from resource-rich regions to energy-hungry markets. The ability to cool natural gas to -162°C (-260°F), reducing its volume by 600 times, is a monumental feat of engineering and logistics.

Here is a deep dive into the complex and essential supply chain that keeps the world powered by LNG.

1. LNG Production and the Export Chain

The journey of LNG begins at the Liquefaction Terminal—a large industrial facility where natural gas is prepared, cooled, and converted into a liquid state.

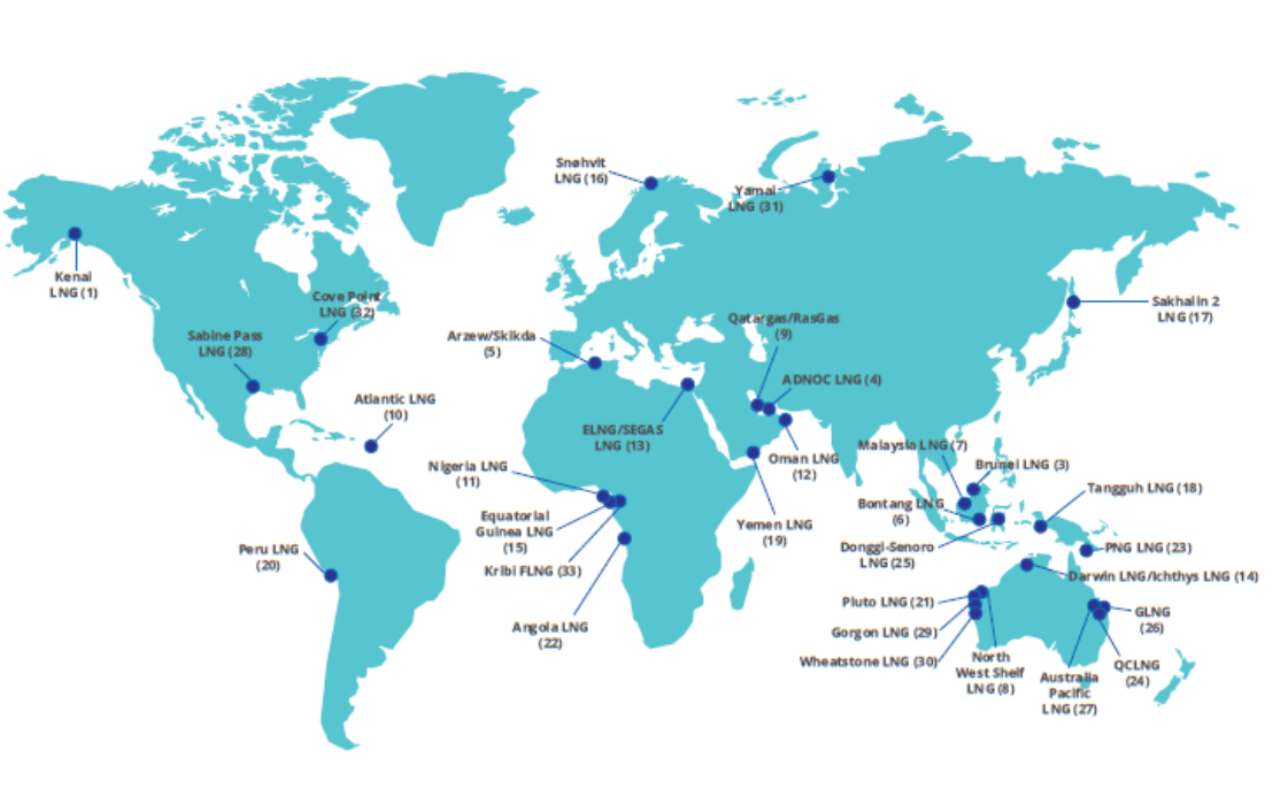

LNG Production Facilities (Liquefaction Terminals)

These multi-billion dollar projects are known for their massive scale and complex technology. They typically consist of one or more processing units called “trains.”

| Region | Major Facilities / Project Names |

|---|---|

| Middle East | Ras Laffan Complex (Qatar), QatarEnergy LNG (World’s largest), Ruwais LNG (UAE) |

| Asia-Pacific | North West Shelf LNG, Gorgon LNG (Australia), Tangguh LNG (Indonesia), Nigeria LNG |

| North America | Sabine Pass LNG, Corpus Christi LNG, Golden Pass LNG (United States) |

Top LNG Exporting Countries (By Volume – Approximate 2024 Share)

The global LNG market has seen a dynamic shift, particularly with the rapid growth of the United States’ export capacity.

| Rank | Country | Estimated Annual Export Volume (BCF/d) | Global Share Indicator |

|---|---|---|---|

| 1 | United States | 11.9 | World’s Largest Exporter |

| 2 | Australia | 10.2 – 10.7 | Stable Major Exporter |

| 3 | Qatar | 10.2 – 10.7 | Stable Major Exporter (Growing with North Field Expansion) |

| 4 | Russia | 4.4 | Significant European Supplier (via LNG and pipeline) |

| 5 | Malaysia | 3.7 | Key Asian Supplier |

Note: ‘BCF/d’ stands for billion cubic feet per day

2. LNG Transport and Storage

LNG Storage

Storage is critical at both ends of the supply chain. LNG is held in large, highly insulated, full-containment tanks at liquefaction terminals and again at regasification terminals. These tanks are designed to maintain the cryogenic temperature of -162°C (-260°F) to prevent the LNG from returning to a gas state.

The Transport Ship: LNG Carriers (LNGCs)

LNG is primarily transported by sea in specialized vessels known as LNG Carriers. These are sophisticated ships featuring highly insulated containment systems to minimize boil-off gas (BOG)—the small amount of LNG that naturally vaporizes during the voyage.

- Containment Systems: Common types include the Moss-type spherical tanks (distinctive large spheres above deck) and the Membrane-type tanks (integrated into the hull structure).

- Size: Modern carriers are often Q-Flex (up to 216,000 m3) or Q-Max (up to 266,000 m3), designed for maximum cargo capacity and efficiency.

- Boil-Off Gas (BOG): Historically, this vaporized gas was used to power the ship’s engines. Modern vessels often use reliquefaction plants or more efficient dual-fuel diesel-electric (DFDE) engines to maximize cargo delivery and efficiency.

Major LNG Shipping Companies

The commercial transport of LNG is dominated by a few major players, often in joint ventures with national oil companies:

- Nakilat (Qatar)

- MISC Berhad (Malaysia International Shipping Corporation)

- NYK LNG Shipmanagement

- Shell Shipping & Maritime Technologies

- BW LNG

Key LNG Transport Routes

LNG trade flows connect major production hubs with consuming markets, often traversing critical global maritime choke points.

| Export Region | Import Region | Primary Routes & Choke Points |

|---|---|---|

| US Gulf Coast | Europe/Asia | Across the Atlantic, often via the Strait of Gibraltar to Europe, or through the Panama Canal to Asia. |

| Qatar/Middle East | Asia | Through the Strait of Hormuz, across the Indian Ocean, often via the Strait of Malacca to East Asian markets. |

| Australia | Asia | Across the Pacific/Indian Ocean to Japan, South Korea, and China. |

3. Regasification and Delivery

The final stage of the LNG supply chain occurs at the Regasification Terminal (Import Terminal) in the consuming country.

- Unloading & Storage: The LNG is unloaded from the carrier and stored in tanks similar to those at the liquefaction site.

- Regasification: The liquid is then heated in vaporizers (using seawater or other heating sources) to convert it back into natural gas.

- Distribution: The re-gasified natural gas is fed into the national pipeline network for distribution to power plants, industries, and residential consumers.

The use of Floating Storage and Regasification Units (FSRUs) has also grown significantly, offering a quicker and more flexible alternative to building permanent onshore terminals, especially in regions with urgent energy needs.

The global LNG market is a complex ecosystem of technology, logistics, and multi-billion dollar infrastructure, constantly evolving to meet the world’s increasing need for flexible and cleaner energy.

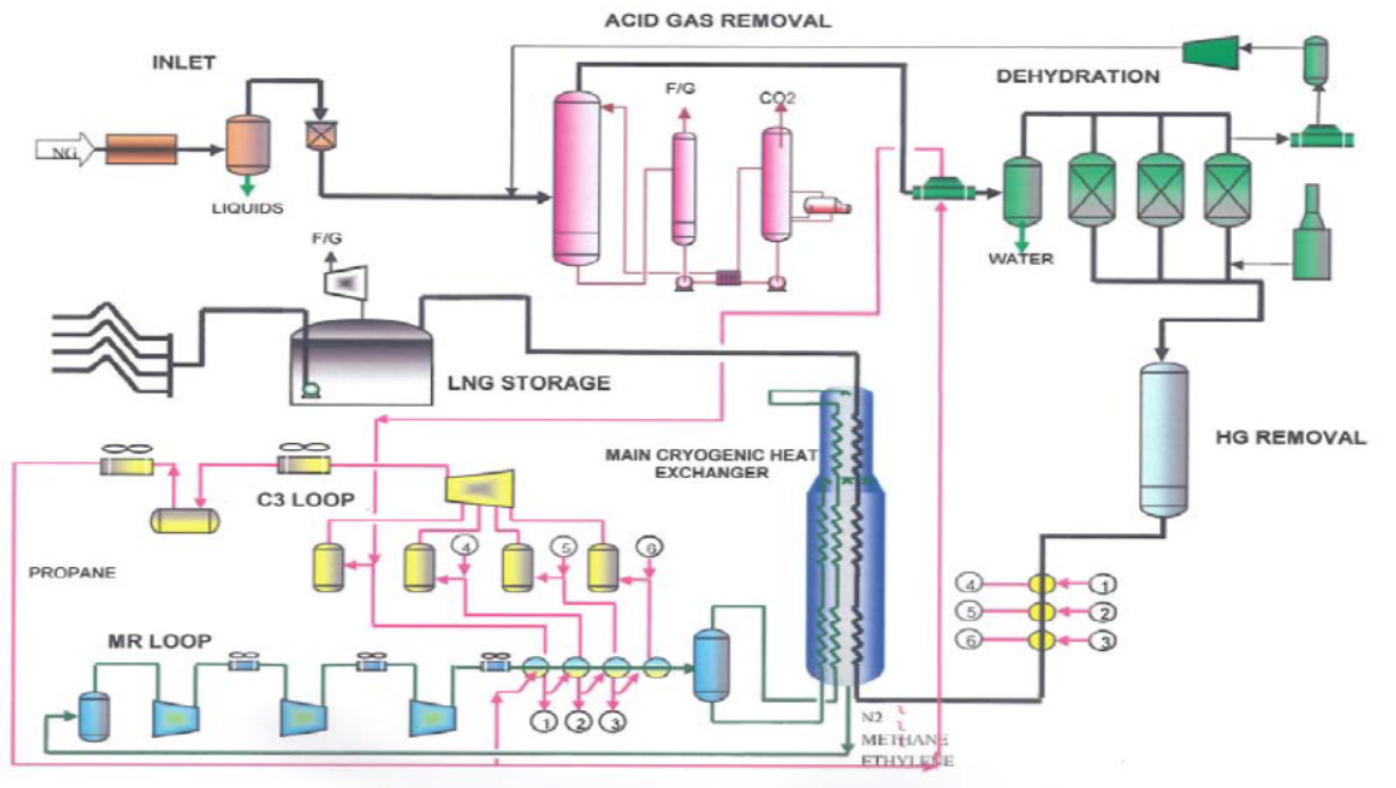

Global Liquefaction Plants Flow Diagram – LNG Processing Plant